The cheese wheels are cared for as if they were children. During maturation, they are regularly brushed with brine.

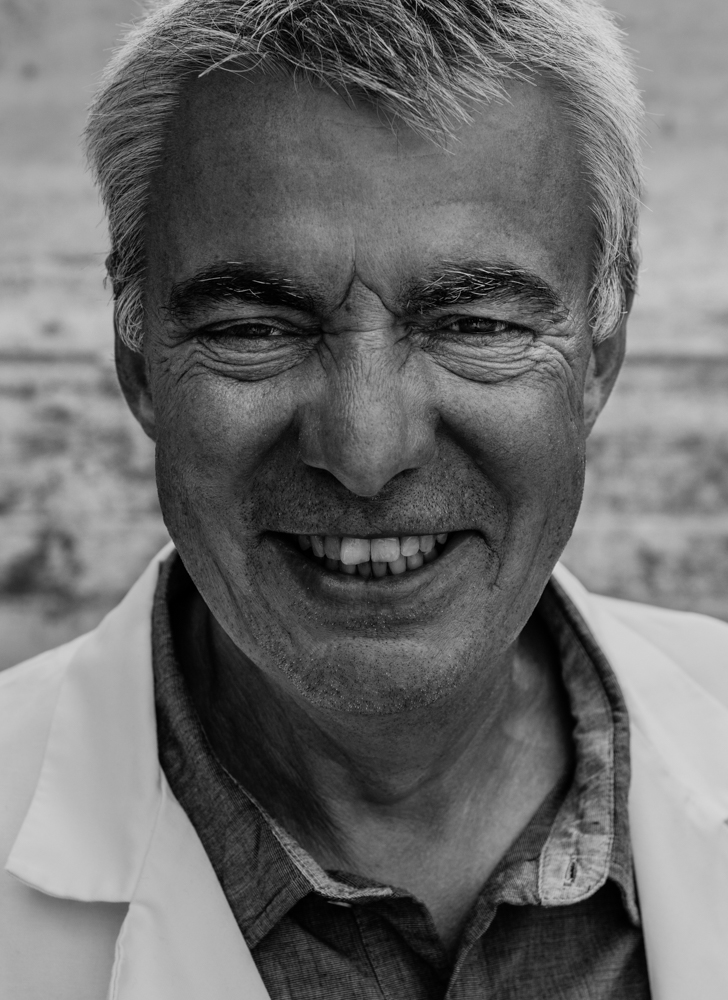

“The cheeses are cared for by robots who don’t have working hours, take days off, or suffer from sore backs! The quality of their work is also consistent, whereas people have the tendency to get sloppy if the work becomes too monotonous”, says the Fromco Moudon cellar manager Jean-Marc Colomb.

In the cellar, the cheese wheels mature on wooden planks. The smell of ammonia tickles the nose, but this is a perfectly normal smell in the maturation environment. The cellar corridors seem to go on forever and forklifts carrying cheese flash by. The length of the corridors is no wonder, since there are as many as 110,000 Le Gruyère AOP wheels maturing in the Fromco cellars. If they were released to the market at the same time, they would need a convoy of 162 trucks to transport them.

Jean-Marc Colomb shows us how the quality of the cheese is checked. He taps on the wheel with a small hammer and listens to the sound. After this, he drills a hole into the wheel and smells and tastes it. At the age of four months, all wheels go through extensive and strict quality control by the authorities. The colour, aroma, and hole formation of the cheese are all evaluated.

Only after it passes the quality control, the cheese can be called Le Gruyère AOP. Only the best quality will enter the market.

The flavour of Gruyère develops and strengthens during the maturation. The light flavour of the classic cheese aged 6–9 months pleases those who prefer mild cheese, while Le Gruyère AOP Réserve, matured for 10 months, already yields a stronger and more aromatic flavour. Some wheels are kept in the cellar for as long as two years; they are intended for lovers of very strong cheese.

“Quality and responsibility are always our most important values at all stages of production. Only premium cheese wheels checked by our cellar masters leave our cellars”, cellar manager Jean-Marc Colomb states emphatically.